In May 2021, AlixPartners predicted that the chip shortage plaguing the auto industry since the middle of the pandemic would end up costing the auto industry $110 billion US in lost revenue through the year, a figure that inflated from an initial $60.6 billion predicted in January. The global consulting firm has updated their estimated revenue loss for the auto industry to an astounding $210 billion US.

That figure nearly doubles the most recent estimated loss of revenue, mirroring the lost vehicle production the global industry faces as the fourth quarter of the year approaches. AlixPartners now predicts that 7.7 million vehicles will be cut from production this year, up from May’s forecast of 2.9 million units.

| Related: Chip shortage update: How it is affecting prices in the new and used market today – Jessica Caldwell, Edmunds |

However, it isn’t solely the lack of available microchips that’s affecting production, although that’s the main influence. In a statement, global co-leader of automotive and industrial practice at AlixPartners, Mark Wakefield, said, “Chips are just one of a multitude of extraordinary disruptions the industry is facing—including everything from resin and steel shortages to labor shortages.

“There’s no room for error for automakers and suppliers right now. They need to calculate every alternative and make sure they’re undertaking only the best options.”

Revised predictions weren’t foreseen

When May’s predictions were made, there appeared to be relief coming for carmakers. After a fire on a production line in March 2021, the Renesas semiconductor chip plant in Japan resumed full production in late June and shipment levels were expected to resume in mid-July. Intel was in talks in April to produce automotive chips at their factories within six to nine months. However, COVID-19 outbreaks in Malaysia closed other factories producing the highly anticipated chips.

“Of course, everyone had hoped that the chip crisis would have abated more by now, but unfortunate events such as the COVID-19 lockdowns in Malaysia and continued problems elsewhere have exacerbated things,” said Wakefield.

Due to the chip shortages, nearly every carmaker is prioritizing their most profitable models on their production lines with the chips that are available. Dozens of plants for Ford, General Motors, Stellantis, VW, Toyota, Honda, and more have been idled at times while they await critical components to complete vehicles.

As an industry, new vehicle inventories are running at approximately one-third their normal levels. Of course, that’s driven up the price that customers are paying for new vehicles, and used car prices are being pulled up to historic levels as well.

New chip factories to end shortage

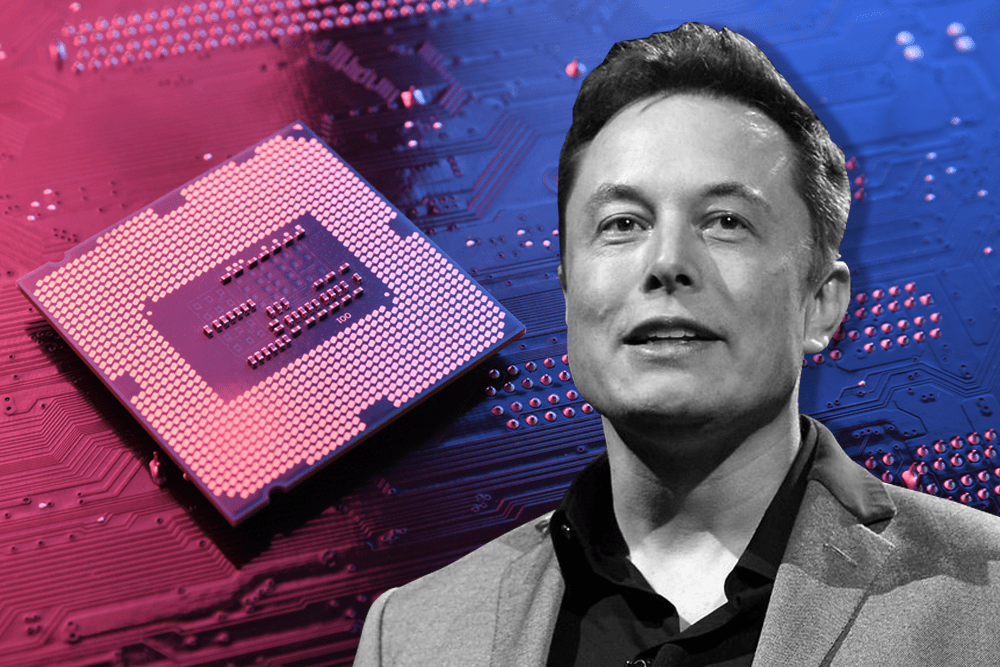

At least one auto executive thinks that there’s an end in sight for the chip shortage problem. At a joint session with Stellantis and Ferrari Chairman John Elkann during Italian Tech Week, Elon Musk responded to a question about how long he thought the global chip shortage would continue affecting vehicle production. His response: “short term I think.”

Musk continued, “There’s a lot of chip fabrication plants that are being built. I think we will have good capacity for providing chips by next year.”

Musk is notorious for having rosy outlooks and timelines, as is evident with model rollouts at Tesla as well as implementation for SpaceX’s Starlink internet service, currently still in beta. However, it’s a sure thing that all auto industry professionals are hoping that Musk’s estimation is right and that the chip shortage will be resolved by 2022.

Did you enjoy this article from Jason Unrau? Please share your thoughts, comments, or questions regarding this topic by submitting a letter to the editor here, or connect with us at newsroom@cbtnews.com.

Be sure to follow us on Facebook and Twitter to stay up to date or catch-up on all of our podcasts on demand.

While you’re here, don’t forget to subscribe to our email newsletter for all the latest auto industry news from CBT News.